Make a Call

+91 8668695262

Metal Conveyor Belt Manufacturers in Pune, Suppliers, Exporters, Dealers in Pune, Chakan

Welcome to Infinity Engineering Solution, your trusted source for high-quality metal conveyor belts in Pune, Chakan. We are the best Metal Conveyor Belt Manufacturers in Pune, suppliers, exporters and dealers in Chakan, Pune.

With a commitment to precision engineering and durability, we specialize in manufacturing top-notch metal conveyor belts that excel in diverse industrial applications.

Our expert team ensures superior performance, longevity, and customized solutions to meet your unique requirements. Explore our range of innovative metal conveyor belts designed to enhance efficiency and streamline your operations.

What is Metal Conveyor Belt?

Metal conveyor belts stand as stalwarts in industrial material handling, offering robustness, flexibility, and reliability. These belts, typically made from stainless steel or other metals, play a pivotal role in diverse industries due to their unique characteristics.

Metal Conveyor Belt in Pune, Chakan

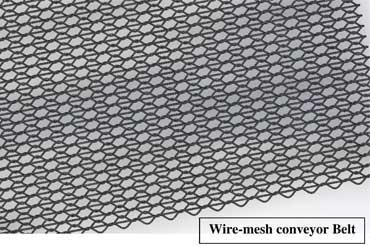

Types of Metal Conveyor Belts

- Flat Wire Belts: Comprising a flat surface for stable transport, these belts excel in applications requiring smooth movement and even weight distribution.

- Chain Link Belts: Formed by interlinked metal chains, these belts are adept at handling heavy loads and provide excellent durability in demanding environments.

- Balanced Weave Belts: Constructed with spirals of left and right-hand wires, these belts offer a stable surface, ideal for precise conveying of small or delicate items.

Reliable Features

- Strength and Durability: Metal belts are engineered to withstand heavy loads and harsh conditions, ensuring longevity and minimal maintenance.

- Temperature Resistance: Withstand extreme temperatures, making them suitable for processes involving heat treatment or cooling.

Advantages

1. Enhanced Efficiency

Metal conveyor belts contribute to increased operational efficiency by facilitating smooth and reliable material transport.

2. Longevity and Reliability

Their durable construction ensures a longer lifespan, reducing downtime and maintenance costs.

3. Versatility

Metal belts accommodate a wide range of applications, from food processing and electronics manufacturing to heavy-duty industrial processes.

Industrial Applications

- Food Industry: Ideal for conveying food products through processes like baking, cooling, and freezing due to their hygienic design and temperature resistance.

- Automotive Manufacturing: Metal belts play a crucial role in automotive assembly lines, facilitating the efficient movement of components during production.

- Heat Treatment Processes: In industries requiring heat treatment or annealing, metal conveyor belts maintain integrity under high temperatures.

Additional Considerations

- Maintenance: While metal belts require minimal maintenance, regular inspection and cleaning are still necessary.

- Tensioning: Proper tensioning is crucial to ensure smooth operation and prevent belt slippage.

- Safety: Always adhere to safety guidelines and regulations when working with metal conveyor belts to prevent accidents and injuries.

- Cost: Metal conveyor belts can be more expensive than other types of conveyor belts due to their material and construction.

Metal Conveyor Belts | Steel Conveyor Belts | Conveyor Belts & Modular Link Belts | Stainless Steel Conveyor Belt | SS Conveyor Belt | Steel conveyor belt | Metal Mesh Conveyor Belt | Metallic Conveyor Belt

FAQ's

-

1. Are metal conveyor belts suitable for handling delicate products?

Yes, metal conveyor belts offer a balanced weave design that provides a stable and gentle surface, making them suitable for conveying delicate items.

-

2. How easy is it to clean metal conveyor belts in food processing applications?

Metal conveyor belts feature a hygienic design, allowing easy cleaning and sanitation, making them well-suited for the stringent hygiene standards of the food industry.