Make a Call

+91 8668695262

Hinge Conveyor Belt Manufacturers in Pune, Suppliers, Exporters, Dealers in Pune, Chakan

Welcome to our premier hinge conveyor belt solutions! Infinity Engineering Solution serve as the leading Hinge Conveyor Belt Manufacturers in Pune, suppliers, exporters, dealers in Pune, Chakan. Engineered with precision, our belts ensure durability and optimal performance, meeting the diverse needs of your industry.

From manufacturing to logistics, trust our Hinge Conveyor Belts to streamline your processes and elevate productivity. Elevate your operations with our Hinge Conveyor Belts in Pune – where quality meets precision.

Hinge Conveyor Belt Manufacturers, Suppliers

Introduction

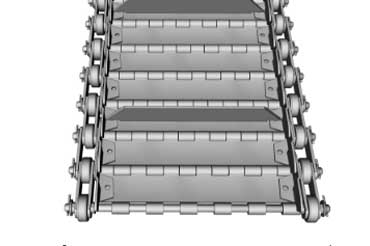

Hinge Conveyor Belts are specialized belts consist of interlinked segments, forming a continuous surface that facilitates the smooth and efficient movement of materials. The Types of Hinge Conveyor Belts are

- Flat-Top Chain Belts: Featuring a flat, smooth surface, these belts excel in handling a wide range of products, making them ideal for industries such as food processing and packaging.

- Flush Grid Belts: Recognized by their grid-like design, flush grid belts offer excellent drainage capabilities, making them suitable for applications in industries like beverage and pharmaceuticals.

- Raised Rib Belts: Equipped with raised elements on the surface, these belts are designed to provide additional grip, making them optimal for incline or decline conveying applications.

Features of Hinge Conveyor Belts

- Modular Construction: Hinge Conveyor Belts are crafted with modular segments, allowing for easy customization, maintenance, and replacement of damaged sections, ensuring minimal downtime.

- High Strength Materials: Built from robust materials like stainless steel or thermoplastics, these belts exhibit durability, corrosion resistance, and the ability to withstand harsh operating conditions.

Exclusive Benefits

- Enhanced Efficiency: The continuous and smooth movement of materials on Hinge Conveyor Belts minimizes the risk of jams, optimizing the overall efficiency of material handling processes.

- Easy Maintenance: Modular construction allows for straightforward maintenance, reducing downtime and facilitating quick repairs or replacements of damaged segments.

- Customization: Hinge Conveyor Belts to specific industry needs by adjusting the belt type, materials, and configuration, ensuring seamless integration into existing systems.

Applications and Uses

Food Processing

Hinge Conveyor Belts play a crucial role in the food industry, facilitating the movement of products during processing, cooking, cooling, and packaging.

Automotive

In automotive manufacturing, these belts contribute to the efficient assembly and transport of components along production lines.

Bottling and Packaging

Industries involved in bottling and packaging benefit from the versatility and precision of Hinge Conveyor Belts, ensuring a seamless flow of products.

Hinge conveyor belts offer a versatile and efficient solution for conveying materials in non-linear paths and overcoming elevation changes. Their flexibility, compact design, and ability to navigate corners and inclines make them a valuable choice for diverse industries and applications.

Hinge Belts | Hinge Belt/Chip Conveyor | Hinged Steel Belt | Steel Hinge Belts | Hinged Conveyor Belt | Hinge Steel Belt Conveyors | Hinged Steel Belting | Hinged Steel Belt Chip Conveyors | Hinge Type Chip Conveyor | Hinged Steel Belt Conveyors

FAQ's

-

1. Are Hinge Conveyor Belts suitable for high-temperature applications?

Yes, many Hinge Conveyor Belts are designed to withstand high temperatures, making them suitable for applications such as baking and heat treatment processes.

-

2. Can Hinge Conveyor Belts be used for inclined conveying?

Hinge Conveyor Belts, especially those with raised ribs or cleats, provide excellent grip and stability, making them suitable for incline and decline conveying applications.